Top Wholesale Warehouse Floor Options from Leading Manufacturers

When I think about the importance of a durable and functional warehouse floor, I can’t help but emphasize its necessity for any wholesale operation or manufacturer. A high-quality warehouse floor not only supports heavy machinery and constant foot traffic, but it also enhances safety and efficiency in everyday tasks. I’ve seen firsthand how investing in the right flooring solution can improve workflow and reduce maintenance costs over time. Whether you’re in need of epoxy, polished concrete, or vinyl, ensuring the floor meets specific industry requirements can make a world of difference. Plus, sourcing from reputable manufacturers guarantees you’re getting a product that stands the test of time. Your warehouse deserves a floor that reflects the professionalism and reliability of your business. Let’s elevate your space with a warehouse floor that’s built to last and help streamline your operations!

Warehouse Floor Application Market Leader

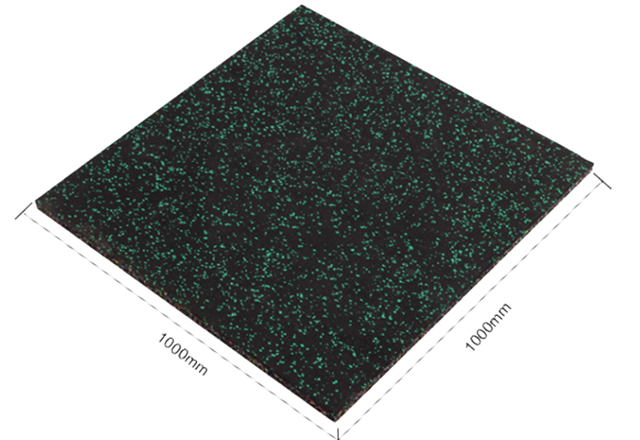

In today's fast-paced industrial environment, the importance of optimizing warehouse floor applications cannot be overstated. As businesses worldwide seek to enhance operational efficiency and reduce costs, leading solutions in warehousing technology are becoming increasingly vital. Effective floor applications not only streamline inventory management but also enhance safety and productivity on the warehouse floor. Innovative materials and designs play a crucial role in shaping these applications. By integrating advanced rubber flooring solutions, companies can ensure durability and resistance to wear and tear, which are essential for high-traffic areas. Such solutions not only contribute to a safer working environment but also aid in noise reduction, ensuring a more pleasant atmosphere for employees. As global demand for efficient warehousing continues to rise, embracing state-of-the-art technologies will empower businesses to stay ahead in a competitive market. Moreover, partnering with industry leaders in warehouse solutions can significantly impact the bottom line. By investing in quality materials and expertise, businesses can enhance their operational capabilities, leading to improved inventory accuracy and reduced downtime. As the warehouse floor application market evolves, companies prioritizing innovative solutions will not only meet current demands but also anticipate future trends, positioning themselves as front-runners in the industry.

Warehouse Floor Application Market Leader

| Application Name | Category | Market Share (%) | Key Features | User Rating |

|---|---|---|---|---|

| WarehousePro | Inventory Management | 25 | Real-time tracking, Automated reporting | 4.5 |

| StockMaster | Warehouse Management | 20 | Inventory optimization, Barcode scanning | 4.2 |

| Track-It | Asset Tracking | 15 | RFID support, Mobile access | 4.0 |

| FlexiStore | Storage Management | 10 | Cloud-based, Customizable views | 4.1 |

| LogiTrack | Logistics Management | 12 | Route optimization, Fleet tracking | 4.3 |

Related Products